Are you keeping track of your Chinese product supplier visits?

Documenting your visit to a Chinese factory is critical!

In today’s article, we bring to you a co-founder of our Amazon FBA business Para Living Inc, Lorenzo, to share a real live report he wrote up after visiting one of our top factory picks for the Sisitano.com brand.

This supplier report is extremely detailed, our team was thoroughly impressed and we want to share this with readers at GFA to understand the importance of a factory visit and documenting.

Now, take it away Lorenzo!

Supplier Trip Report Friday 03 November 2017

Yesterday I went to the office of the 3rd supplier with Ino from Insight-quality.com. Ino picked me up at the train station in Yiwu at 9am and we drove for about an hour to Jinhua, where their office is located. We were greeted by the very helpful and cheerful assistant. The factory owner of the company was awaiting us in the office and greeted us warmly.

We went into the showroom where there were so many different styles, colours that I felt like a kid in the proverbial candy store. 🙂 We can really build a long lasting relationship with this supplier and offer a very large selection of styles, colours of espresso makers as well as other styles like the French style, the Turkish, Arabic style etc and other coffee accessories.

As soon as I got there, I explained to the factory owner what are the 3 main most commonly encountered complaints by the majority of the customers of espresso/moka makers and we need to have those fixed:

While at Meir’s house last Saturday in Shenzhen, when we tested the espresso makers, we also experienced all 3 of these issues on all the espresso makers that we tested.

With that mentioned to the factory owner, he explained to us how we can address those issues.

Regarding the handle getting too hot and burning the hand, he mentioned that we can simply change the material of the handle from a basic plastic to one that is fire resistant nylon. The cost to change the handle on the classic italian 6 cup espresso maker from the standard non fire resistant to one that is fire resistant is an extra 33 cents on each unit.

In regards to water leaking, he explained to us that a standard gasket is between 2.5 to 2.7 cms and that we can replace the standard gasket with a thicker one which is between 3.8 to 4cms and that would solve the leaking. He also mentioned that there are 2 types of materials for gaskets, rubber and silicone. As per Ino, we cannot use rubber gaskets in the US, so that leaves us with the silicone one as the logical material to go for. The silicone gasket is softer than the rubber one.

In regards to addressing the aluminum particles being present in the coffee, the factory owner said that he will make a new sample where he will polish for longer the inside of the espresso maker and that should fix the issue of having aluminum particles in the coffee. He said it will take about a week for that sample to be made and he will test it then.

I also explained to him that our initial order will be for 500 units to test the market and if the test is successful, then we’d be placing an order for 1000 units shortly after. He is ok with that.

After explaining and emphasizing that we need to have an espresso maker that addresses all these 3 issues, I looked at quite a lot of different styles and colours of espresso makers. The 3 that I really liked are the following ones:

Style 1: Classic traditional Italian 6 cup espresso maker (the original one we looked it and for which we got samples for).

Details:

Classic traditional grey colour.

Aluminum made.

Works on both electric and gas stoves.

Inside and outside polished.

Standard handle non fire resistant.

each for non fire resistant handle units.

extra each for fire resistant nylon handle units

Thicker silicone gaskets 3.8-4 cms is extra

Delivery time: 30 days for 500 and 1000 units.

Silk screen and Laser logo engraving (5 cents each), laser is classier and more durable.

Standard Colour box with customized design, negotiated to have it free of charge.

For higher quality/stronger box, extra each. Box is a lot more solid, well worth it!

Cost of 500 of Style 1:

Non fire resistant handles:

Cost of 500 with fire resistant handles:

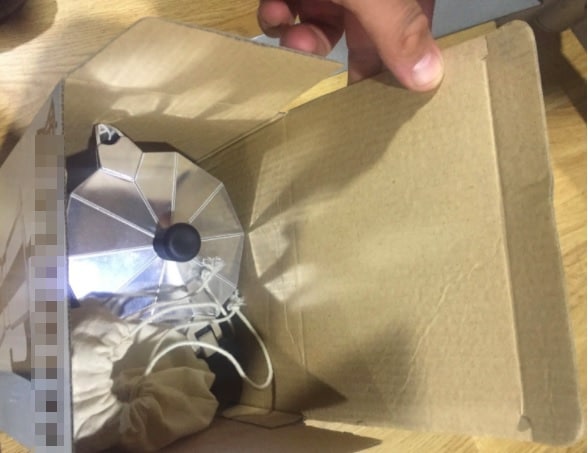

Pic below:

Style 2: Brown/Grey with wooden looking handle, inside polished, outside coating, for both electric and gas stoves.

Grey and Brown models shown below.

Grey/Brown colour.

Aluminum.

Aluminum filter.

Inside polished.

Outside coating.

Transparent top.

Wooden looking handle made of silicone (NON Fire resistant).

Can replace it with a fire resistant nylon handle (one colour only, ie: black).

Can work on electric and gas stoves.

Delivery time: 30 days for 500 and 1000 units.

for the non fire resistant handle unit.

for the fire resistant handle unit.

Thicker silicone gaskets 3.8-4 cms is extra/each.

Silk screen and Laser logo engraving, laser is classier and more durable.

Standard Colour box with customized design, negotiated to have it free of charge.

For higher quality/stronger box, extra each. Box is a lot more solid, well worth it!

Cost of 500 of Style 2:

Non fire resistant handles:

Cost of 500 with fire resistant handles:

Pics of the brown and grey below:

Other colors for this style available.

Bottom of the above ones which can be used on both electric and gas stoves.

Style 3: High quality classic Italian 6 cup espresso/moka maker, fire resistant handle, all surface stoves.

Stainless steel boiler and filter.

Polished top inside and outside, made of aluminum.

Inside the boiler sand blasting.

Can be used on electric, gas and induction stoves.

Fire resistant handle.

Thicker silicone gaskets 3.8-4 cms is extra/each..

Delivery Time: 30 days for 500 and 1000 units.

Silk screen and Laser logo engraving , laser is classier and more durable.

Standard Colour box with customized design, negotiated to have it free of charge.

For higher quality/stronger box, 5 cents extra each. Box is a lot more solid, well worth it!

Cost of 500 of Style 3:

Below you can see the difference between a stainless steel and an aluminum filter. The darker, much more sturdy, solid and durable one is the stainless steel one.

Bottom of the 3 surface (electric, gas and induction stoves) espresso maker:

It looks and feels so much more classier with the heavier stainless steel material.

Packaging

For boxes, the factory owner said that he would make the boxes a little longer to fit our accessories and make the area facing the mouth of the espresso maker to have a double wall to protect the box and the espresso maker.

I negotiated with the factory owner to have colour boxes with custom design/logo on it at no extra cost. He agreed to that. 🙂

Below are pics of the style of packaging/boxes he showed us that we can get at no cost including the design, which I had to negotiate for and obtained. 🙂

For custom made boxes with nice window display as shown below, the MOQ on those is 4000 units and delivery time is 35 days

Styles of packaging they have available as shown above. We should look into those for the 2nd round.

Regarding payments:

2 methods of payment, through T.T. and AliBaba’s insurance escrow.

He mentioned that if payment is done through AliBaba, AliBaba requires the supplier to do the export documents in order for them to confirm the product quantity and quality.

30% down payment and the rest (70%) upon completion.

I asked how about if there were any QC issues with products, he said we’d have to contact him and he’d replace them at no cost. Obviously, we’d have to have that clearly included in our contract with them.

Note: I asked him that based on his 20 year experience manufacturing and selling espresso makers to customers around the world, most of his customers ordered the standard non fire resistant handle units. And I asked him, based on his experience, which style is the most popular among his clients, he said without hesitation, the classic style (model 1 and 3).

I asked him where are most of his customers located and he said in Europe. From what I saw on the boxes displayed in his office and show room at the factory, that they are in Italy, Spain, Portugal and Brazil as I could read them, they were in Spanish and Portuguese.

As per Roland’s request, I asked the factory owner if we could have a fire resistant wooden handle made. He said that we could but it’d be very difficult for the following reasons:

Wood is a combustible by default.

We’d have to open a new mould which would cost be high and we’d keep the mould.

Perhaps that’s an option we could explore later on in our journey. However, at this stage as we’re just starting, I don’t believe we’d need that just yet. Later on, it could be a great upgrade.

Supplier Report Conclusion

Amazing report on the supplier Lorenzo! This is making me excited about our Global From Asia investment in this new Amazon FBA business – Para Living. As a shareholder – we are feeling good right now that we have the right people and processes in place.

We hope you are also doing these kind of supplier reports when you visit your factories. Meeting them in person is priceless and will help keep your relationship high!

One Comment on “Documenting Your Chinese Factory Visit: Example Supplier Status Report”

Pingback: Next Steps on our First Order and First Amazon Private Label Listing - GFAE016